Shopping for high-quality wood restaurant chairs can be seriously confusing. It is important to gain some understanding of how to make a good selection before making the final purchase. Wood has been the top-choice for most restaurant owners as it offers a wide assortment of styles, materials and construction techniques. The exceptional durability, unique aesthetic appeal and ease of construction make wood a popular and versatile material for making wood chairs.

Main Components of Quality in Wood Restaurant Chairs

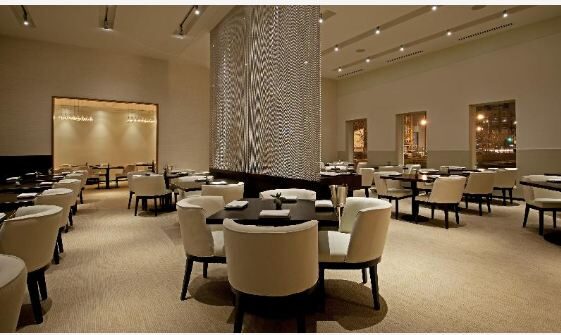

Wood restaurant chairs are a good choice if you want to project a quality image to your customers, but consider keeping the design simple and based on the theme that you are trying to project. Below are some important aspects of buying quality wood chairs for your restaurant or business.

1. Type of Wood

Wood chairs for restaurants are made of different types of wood that can be majorly classified as hardwood, softwood, or engineered. The type of wood will help you determine the chair’s life and how it will fare with age. Hardwood comes from deciduous trees, and is known for its quality in furniture. The deciduous trees include all leaf bearing trees such as oak, maple, teak, walnut, cherry and birch. Pine, which is a soft wood, is also used to make quality wood restaurant chairs and furniture, but requires more care since it is more susceptible to scratches and dents than harder woods like oak, and can be much bulkier to make up for the lack of strength. Solid wood has been a common choice for making restaurant chairs. However, the chair backs and aprons can be made out of veneer plywood, or engineered wood for its high durability and strength. Plywood and engineered wood can also eliminate warp age, splitting, expansion, and contraction, making attractive chairs.

2. Construction

The way the parts of the wood chair are joined and sturdiness of the wood chair greatly impacts its construction quality. How the joints are put together determines the durability and appearance of commercial wood chairs. Quality made wooden chairs may have compressed tenon joints where two pieces of wood join for the best type of wood joint. Lower priced chairs may get their lower prices from lack of precise details in the manufacturing process. Joints where two pieces of wood come together are critical for the chair’s longevity.

What this means to you is that you may get the impression that two chairs look identical except one has a much lower price. Inspect the details before purchasing because the lower price chair construction chairs may only last for one year and then fall apart. To test chairs yourself, put your knee on the seat and with your arms, try and twist the sample. The chair should be silent to show you one part of quality construction. Too much squeaking of the chair may indicate loose chair joints and a red flag that there may be maintenance issues in the near future.

3. Finish

A good finish is very important to enhance the overall quality of the furniture piece. The finishing process involves three steps – sanding, staining, and finishing. Each of these three steps is equally crucial and neglecting any of these steps in the process can seriously affect the overall look and feel of your wood chair. It starts with sanding, wherein the chair is sanded smooth. Check for blotchiness or scratches by looking at the finish through different angles which indicate poor sanding. High quality staining will have evenly applied stain, without any dark sports on the wood surface.

A good stain greatly enhances the natural charisma of wood, and adds color and character to the wood. With the right staining, you can make different woods look similar and similar woods look different. Wood chair finishes range from high-gloss to matte. A high quality finish is free from dust, bubbles or rough spots, and is smooth. Good finishing ensures the edges and ends are well-coated, free of finger marks, and the filled cracks and holes are covered with top finish. The chair back and underside should also be finished to reduce future swelling or shrinking.

Conclusion

The main thing for you to know about wood chair finishes is that you need a quality finish so that the oils from customers hands will not break down the finish. You may have seen sticky chairs before or gummy kitchen cabinet doors and that represents a finish that is breaking down. The sticky chair cannot be cleaned, only an expensive re-finish can be done to restore the chair to its original condition. So pick a chair that has oil and chemical resistance top coat finish.